- Efficient AutomationAutomation equipment covers the entire production process, reducing manual intervention, lowering labor costs, and improving production efficiency.

- Modular DesignThe production line can be flexibly adjusted based on different product requirements, easily handling multiple processing needs, maximizing your return on investment!

- Advanced and Thorough CleaningUses multiple cleaning technologies such as bubble cleaning, vortex cleaning, and high-pressure spraying to thoroughly remove dirt and pesticide residues. The water recycling system reduces water waste.

- Customizable Production FlowThe production line can be customized based on capacity requirements and plant layout, ensuring optimal production efficiency.

Key Features

Applications

Carrot

Potato

Sweet Potato

Taro

Onion

Spinach

Lettuce

Cabbage

Chinese Cabbage

Video

Process Flow

-

Soaking (For Root Vegetables)

The soaking elevator is equipped with a bubbling system that agitates the water, effectively loosening and removing dirt and sand from the surface of root vegetables. This ensures an initial cleaning process.

-

Peeling

The brush roller peeler removes the skin of root vegetables through high-efficiency friction. It is equipped with an automatic spraying system that simultaneously washes the materials.

-

Cleaning

The bubble washing machine uses an air-bubble water bath cleaning system, combining bubbling and spraying to wash vegetables multiple times, thoroughly removing surface contaminants.

-

Sorting

The sorting workstation is used for material selection, pre-cutting, and conveying. It serves as a pre-processing unit in the production line, ensuring material quality for the next stage.

-

Cutting

The multifunctional vegetable cutter is equipped with two cutting heads: one dedicated to cutting leafy vegetables and the other specialized for root vegetables.

-

Deep Cleaning

The vortex washing machine utilizes vortex flow to create strong, irregular flipping movements in water, effectively removing surface residues from the cut materials.

-

Sieving

The vibrating screen not only removes impurities but also reduces moisture content through oscillation, shortening the processing time for the next stage.

-

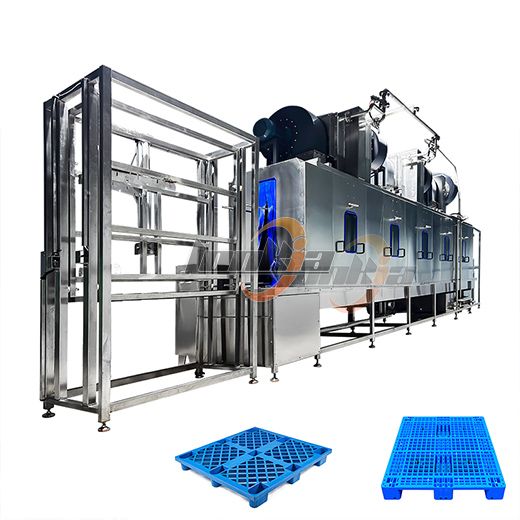

Air Drying

The air drying machine removes excess moisture from the screened vegetables, making them easier to package and store.