- Multi-stage CleaningUses a combination of brush rollers and bubble cleaning to thoroughly clean the cucumber surface, preserving its natural quality.

- Efficient FillingAutomated cucumber and brine filling equipment, accurate and efficient, suitable for different can sizes and capacities.

- Secure SealingSteam vacuum sealing technology ensures can sealing, extending shelf life of the product.

- Uniform SterilizationPrecise sterilization control ensures the safety and hygiene standards for every can of product.

Key Features

Applications

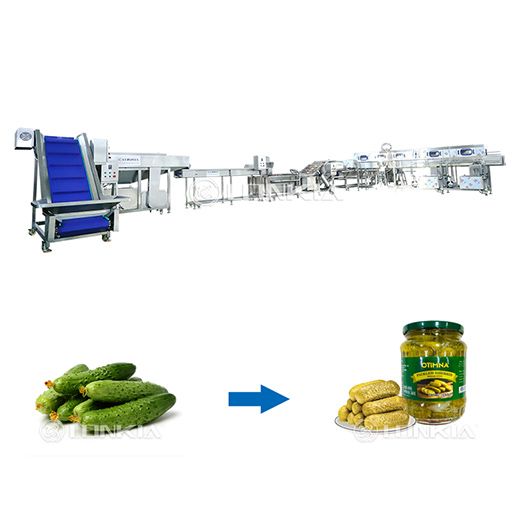

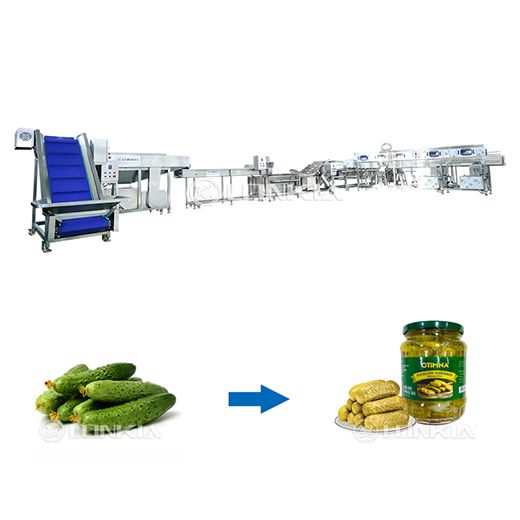

Canned Cucumber

Canned Cucumber

Canned Cucumber

Canned Cucumber

Video

Process Flow

-

Parallel Brush Roller Cleaning

Uses parallel brush rollers to remove spines and dirt from cucumber surfaces, preparing them for the next cleaning step.

-

Blanching

Quickly treats cucumbers with hot water to preserve their green color and crisp texture while preventing discoloration or spoilage during further processing.

-

Bubble Cleaning

Utilizes a bubble washer to remove remaining residues and impurities from blanching.

-

Empty Can Depalletizing and Cleaning

Automated equipment separates stacked empty cans and cleans both their interior and exterior using a clamp-type washing machine, ensuring hygiene for filling.

-

Automated Cucumber Filling

Precisely places whole cucumbers into cans, ensuring neat arrangement and enhancing product aesthetics and uniformity.

-

Brine Filling

Automatically fills pickling brine into cucumber-filled cans, ensuring even distribution without spillage.

-

Steam Vacuum Sealing

Replaces headspace air with steam and quickly seals in a steam environment. Condensed steam creates a vacuum, extending shelf life and preventing oxidation.

-

Sterilization Line

Performs high-temperature spray sterilization on canned products, ensuring safety and shelf life.