- High Automation & Efficient ProductionFrom de-stemming and cleaning to filling and sealing, all processes are fully automated, reducing manual intervention and improving production efficiency.

- Precise Filling & SealingPrecise filling technology ensures consistent weight per can, and perfect sealing extends shelf life.

- Efficient Cleaning & De-saltingThe bubble washer and de-salting equipment work efficiently together to ensure clean chilies with better taste.

- Reliable Hygiene & SafetyAutomation greatly reduces the risk of contamination, ensuring the production process meets strict hygiene standards.

Key Features

Applications

Business Trip

Business Trip

Business Trip

Business Trip

Business Trip

Business Trip

Process Flow

-

De-stemming

The de-stemming machine automatically removes the stems of the chilies, ensuring each chili is cleaned and prepared for the next steps. Automation reduces labor costs and improves production efficiency.

-

De-salting

For pickled or salted chilies, the soaking de-salting machine removes excess salt from the chilies, ensuring the flavor is not affected.

-

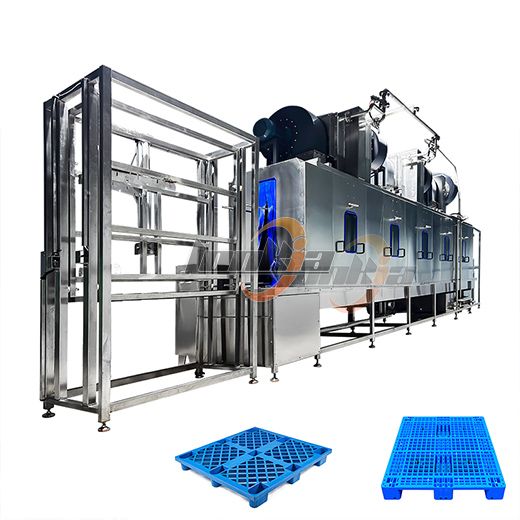

Empty Can Unstacking & Cleaning

Automated equipment separates stacked empty cans and cleans both the exterior and interior of the cans with a fully automatic bottle washer to ensure hygiene before filling.

-

Filling

The filling machine precisely fills the processed chilies with the seasoning liquid into cans, ensuring each can has the same weight and liquid amount.

-

Sealing

The sealing machine seals the chili cans, preventing external air and microorganisms from entering. Good sealing ensures an extended shelf life for the chili cans.

-

Sterilization

The automated sterilization kettle applies high-temperature sterilization to the sealed chili cans, ensuring that bacteria and microorganisms are destroyed.